Calcium Silicate Board / Fiber Cement Board Production Line

Tsanangudzo Pfupi:

NeFiber Cement Board Zvigadzirwa Zvakawanda Kushandiswa Mukuvaka uye Kushongedza Indasitiri,

Product Detail

Product Tags

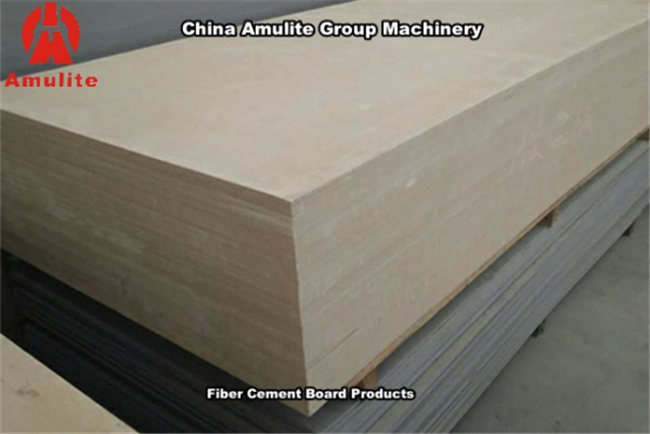

Iine Fiber Cement Board Zvigadzirwa Zvakawanda Kushandiswa Mukuvaka uye Kushongedza Indasitiri, Fiber Cement Board Kugadzira Line Technology Uye Otomatiki Level Gara Ramba Uchisimudzira Nguva Yese.Ne Kuenderera Kuedza KweAmulite Injiniya Chikwata Isu Tinogara Tichichengeta Tekinoroji Yekuvandudza Uye Kuita Yedu Fiber Cement Board Michina Ive ln. Higher Level MuWorld Cement Board Products Market ;Iyezvino Tave Nenguva Dzose Kugadzira Uye Kugovera Fiber Cement Board/Calcium Silicate Board Production Line Ine Kugona 3Million Sq.m Pagore.4Miriyoni Sq.m Pagore.6Million Sq.m Pagore ,8Million Sq.m Pagore,10Million Sq.m Pagore Nguva dzose;Standard Board Size 2440X1220X(4-25)MM Uye 3000X1220X(4-25)MM,Tinogonawo Kugadzirisa Manufacturing To Customers Equipment ' Chinodiwa, Chero Customized Specification Inogona Kuzadzikiswa;

Mhando Uye Zvimiro

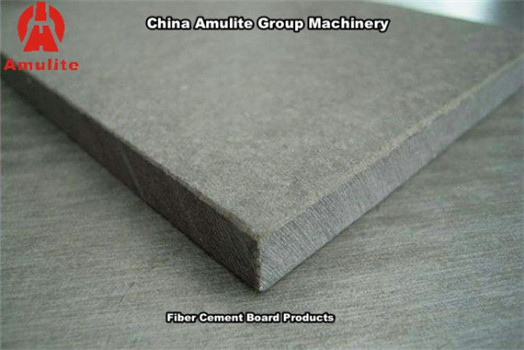

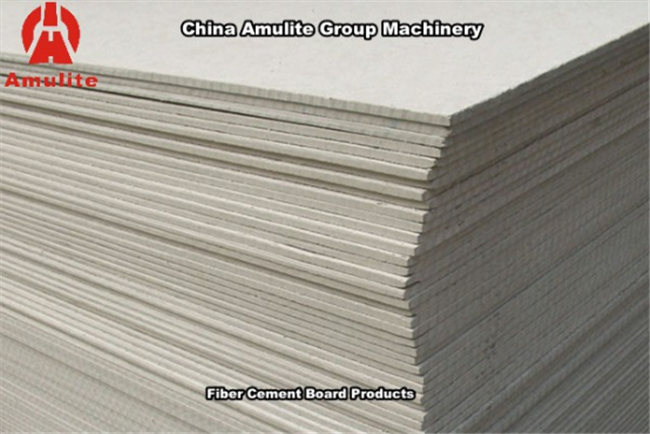

Fiber Reinforced Calcium Silicate Board/Fiber Cement Board Uyewo Danai Se CSB/FCB Board.SeRudzi Rutsva Uye Dziviriro Yekuvaka Zvishandiso,Iyo Iine Advantage YeChiedza Weight.High Strength,Fireproof,Good Heat Insulation Performance.Wide Usage Uye Hupenyu Hwakareba Etc. Iye zvino Calcium Silicate Board/Fiber Cement Board Zvigadzirwa Zvinoshandiswa Zvakawanda Mukuvaka Ceiling uye Partition.High Building's Exterior Insulation,Public Building Fireproof Panels,Ceiling Tiles,Air Duct.Ship Partition Panels Uye Fire Escape Path Inside Buildings Etc;

Production Technology

Calcium Silicate Board/Fiber Cement Board Tora Inorganic Fibers Kana Cellulose Fiber SeFiber Yakasimbiswa Materials.Tora Calcium Uye Silicate Materials SeMain Cementing Materials.Ne Production Process Slurry Mixing,Board Kuumba.Board Stacker,Pre-Curing,Demold Template,Autolave Curing Gadzira Kunze, Kune Zvimwe Zvepamusoro Standard Board Zvinodiwa.Unogona Kuwedzera Bhodhi Press, Bhodhi Kuomesa, Bhodhi Sanding uye Edge Trimming Maitiro, uye Ita Pendi Pachiso Kuvandudza Bhodhi Standard uye Kushandiswa, Wobva Wawedzera Zvakawanda Nezve Bhodhi Yakawedzera Kukosha uye Kukurisa Bhodhi Rekutengesa Soko. ;Yekugadzira Bhodhi Maitirwo ECalcium Silicate Board/Fiber Cement Board Production Line Kazhinji Inotora Flow-On Slurry Forming Type,Hatchek Kugadzira Rudzi Uye Extrusion Type.

Main Raw Materials

Yakasimbiswa Fiber (Kraft Paper Pulp,Wollastonite,Glass Fiber.Mica Etc),Silicate Materials (Quartz Sand,Fly Ash, Diatomite Etc},Calcium Materials(Lime Powder, Cement),Additives Etc.

Products Standard.

Calcium Silicate Board Industry Standard JCIT564-2008Fiber Cement Board Indasitiri Standard JCIT 412.1-2006

Production Process sumo

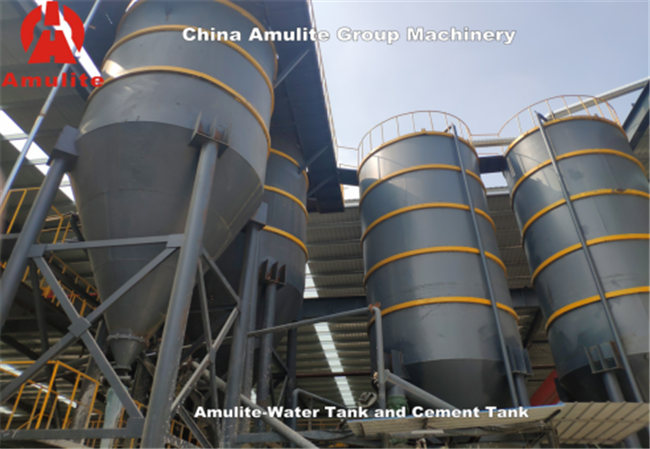

1.Water Tangi Uye Simende Tangi Process

Kune Rimwe Tangi Yemvura Yakachena Uye Imwe Tangi Yemvura Ine Madhaka; Maviri Tangi Emvura Muviri Akasungwa NeCarbon Simbi, Iyo Tangi Yemvura Yemadhaka Inoshandiswa Kuunganidza Kudzoreredza Mvura Kubva Mashizha Kugadzira Mashizha, Mvura Yemadhaka Tora Kusanganisa MuSlurry process, Yekuchena. Tangi Yemvura Inoshandiswa Kutora Mvura Yakachena Kuchenesa Felt uye Net Cage Kazhinji.

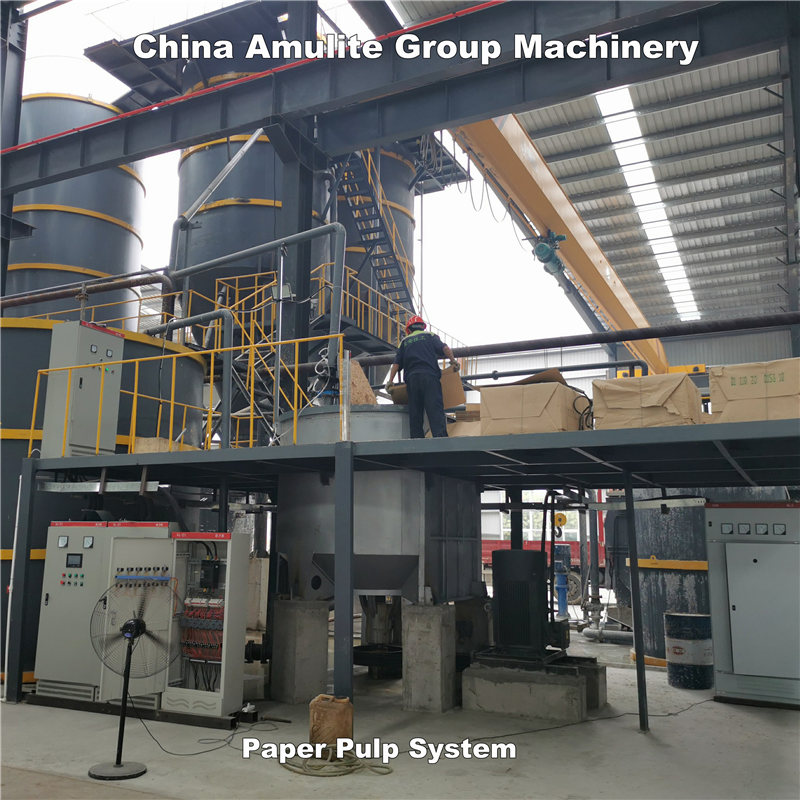

2.Pepa Pulp Process

Pepa Pulp Maitiro Inosanganisira Pepa Shredder Machine, Refiner, Uye Pepa Pulp Storage Tangi.

Pepa Shredder Inoshandiswa Kubvisa Iyo Kraft Papers

Refiner Yaishandiswa Kukuya Pepa Pulp kuita Slurry uye Kuipomba kune Pepa Pulp Storage Tangi.

Paper Pulp Storage Tangi Inoshandiswa Kuchengeta Iyo Pepa Pulp.

3. Flow-On Slurry Vacuum Water Dehydration Process

Tinogona Kusarudza Flow-On Slurry Kugadzira Sheets Sisitimu Kana Hatschek Mhando Kugadzira Sheets Sisitimu Kuti Iumbe Sheet, Tinogona Kugadzirisa Zvinoenderana Nekudiwa kweVatengi.

Yakanyatsosanganiswa Slurry Inoyerera MuKuyerera-PaSlurry Bhokisi, Wobva wabva kuSlurry Bhokisi Kuendesa Kumhanya Kunzwa Kugadzira Slurry Layer, neVacuum Dehydration uye Chest Roller Press Kuti Uumbe Sheet Layer, Mushure meLayers Kutenderedza Round Kugadzira Sheets Drum Roller, Wobva waita otomatiki Kucheka To. Form Flat Wet Sheets .

Mhepo-Mvura Separator: Inoshandiswa kupatsanura Musanganiswa weMvura yeSteam yakatorwa kubva muBhokisi reVacuum, inoyerera ichipinda mutsime rekuunganidza, uye mweya unodhonzwa uchidzokera kuPombi yekutsvaira.

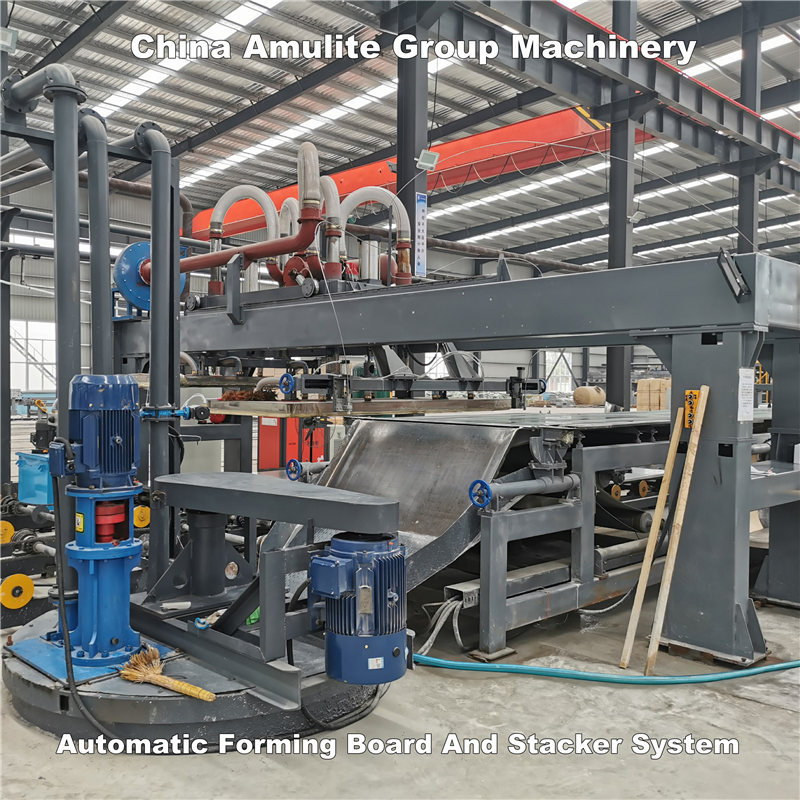

4.Flow-On Slurry Sheet Kugadzira Maitiro

Mushure meKugadzira Roller Kugadzira Mashiti, Wobva waita otomatiki Laser Positioning uye Kucheka, Yese PC Yemashiti Akanyorova Inopinda Munzira Yekufambisa.

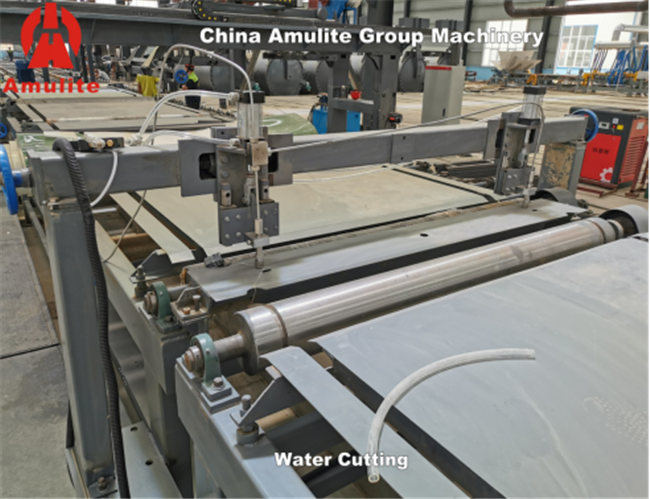

5.High Pressure Water Cutting System

Iyi Yepamusoro Yekudzvanya Mvura Yekucheka Sisitimu Yedu Yedu Patent Equipment, Iine Yakakwira Yakanyanya Kudzvanya Pombi Yemvura Kuita Yakanyanya Kudzvanya Mvura Kuita Kucheka Kucheka Kwemashiti Akanyorova PaConveyor.

6.Kugadzira Wet Sheet Uye Wet Sheet Conveying Process

Iyi Maitiro Inoshandiswa Kuburitsa Iyo Yakachekwa Yakanyatsonyorova Sheet Kubva Mukugadzira Roller Kuendesa Mashizha Akanyorova Kuti Amire Uye Otomatiki Kucheka Kucheka.

7. Automatic Stacker

Mashiti maviri anogona kuiswa panguva imwe chete.Mukombe Wekusveta Unosveta Mashizha Akanyorova Kubva Pakugashira Conveyor muchina uye Templeti PaTrolley Pane Imwe Nzvimbo Yekushanda, Wozoaturika PaTrolley Pakati Penzvimbo (Nekusveta kweVacuum YeFan Yekudzvanya Kwakanyanya).Iko Kufamba Kwechokwadi Kwemukombe Wekusveta Kunozadzikiswa Negiya Paruwoko Rwekuswing Runosundirwa neHydraulic Push Rod.

PLC Kudzora, Kushanda Otomatiki.

Basa: Iyo Otomatiki Stacker Inoshandiswa Kuronga uye Kuisa Hunhu uye Yakaderera Zvigadzirwa zveFiber Cement Board/Calcium Silicate Board.

Izvo Zvigadzirwa Zvakarongwa Zvakarongeka Uye Zvakanyanya Otomatiki, Zvinozonyatso Kuvandudza Kubudirira Kwekugadzira.

8 .Press Machine

Press Machine Inoshandiswa Kuwedzera Density uye Kusimba Kwezvigadzirwa,

Standard Pressure: 7000ton, Press Tafura Size: 1350 * 2700 / 3200mm, Spacing: 1200mm, Kushanda sitiroko: 400mm, Pressure Speed: 0.05 ~ 0.25mm / s;

Kudzoka Kumhanya: 15 mm / S

Mukati uye kunze kwePress Transport Mota: Imwe Unit.

Simba: 27.5kw

9.Trolley Traction System

Inobvumirwa Mutoro: 20T

Tafura Rail Inner Distance: 750mm

Kufamba Mechanism:

Reducer Model: fa67-60-y-1.5, I = 50

Kufananidza Mota Yekumhanya: 1380r / min, Simba: 1.5kw

Kufamba Kumhanya KweTrolley: 9m / min

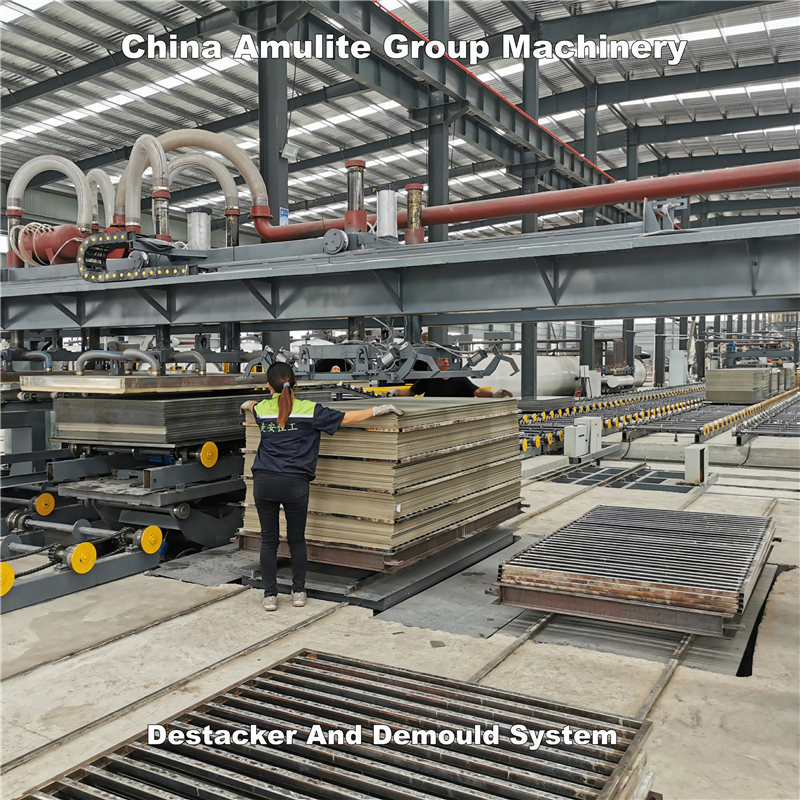

10. Vacuum Demoulding Template Machine

Kufamba Kwemota uye Kusimuka nekudonha kweSuction Cup kunodzorwa neServo Motor.

Muchina weDemoulding Template Unopatsanura Template Uye Mashizha PaTrolley, Template yacho inoiswa Pamushini weOil Brush Kuti Ukweshe Oiri, Uye Mashizha Anotutirwa Kune rimwe Side Trolley.Wedzera Imwe Autoclave Interleave Spacer Yese 150 mm Mashiti.

Kufamba Kwechokwadi Kwemukombe Wekusveta Kunozadzikiswa Negiya Paruwoko Rwekuswing Runosundirwa nePneumatic Push Rod.

PLC Kudzora, Kushanda Otomatiki.

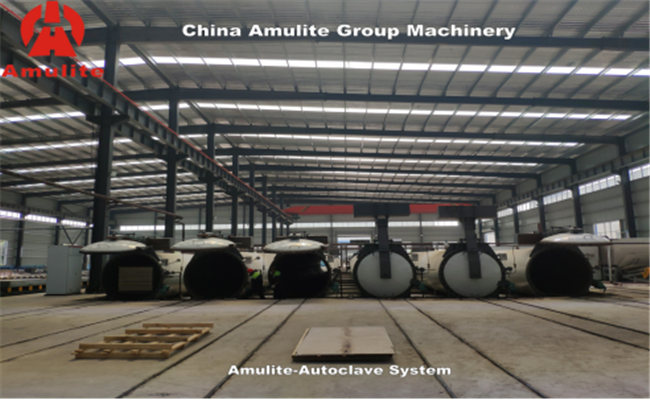

11.Autoclave Process

Nekuda kweHunhu hweFiber Cement Board/Calcium Silicate Board, Lime uye Quartz Sand Powder Inoshandiswa SeIyo Yakakura Zvishandiso Mukugadzira Maitiro, Inoda Kuwana Kemikari Yekuita Pasi Pekupisa Kwekupisa Uye Kunyanya Kudzvanywa Kwenzvimbo, Inogona Kurega Zvese Raw Materials Akasanganiswa. Zvakwana, Uye Ita Mashiti Zvirinani Kuoma uye Kusimba.

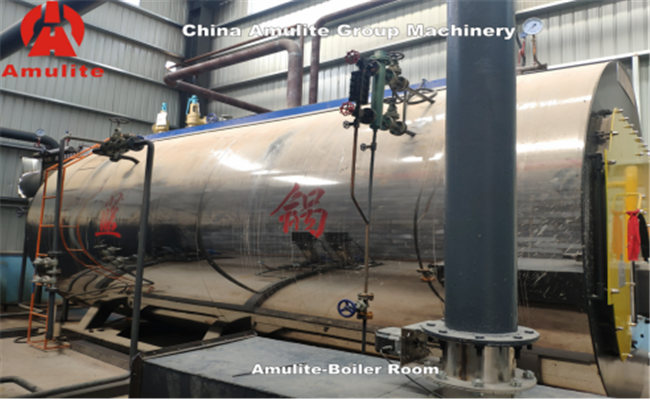

12.Boiler

Mukugadzirwa kweFiber Cement Board/Calcium Silicate Board, Autoclave uye Dryer Inoshandiswa Kugadzira, Uye.

Iko Kupisa Kwesimba reAutoclave uye Dryer Inopihwa neBoiler!

13. Dryer

Iyo Inoshandiswa Kuomesa Fiber Cement Board/ Calcium Silicate Board, Mushure me Autoclave Kurapa, Hunyoro Hwemukati weFiber Cement Board Inenge 25%.Pamberi peSanding, Edging uye Chamfering, Hunyoro

Zvemukati Zvinofanira Kudzikiswa Kudzika Kupfuura 15% Neyakaoma.Iyo Dryer Iine Zvakanakira Zvekukwira Kubudirira Kwekugadzira, Kutaridzika Kwakanaka, Kugadzirisa Kwakaringana uye Kushanda Kwakareruka.

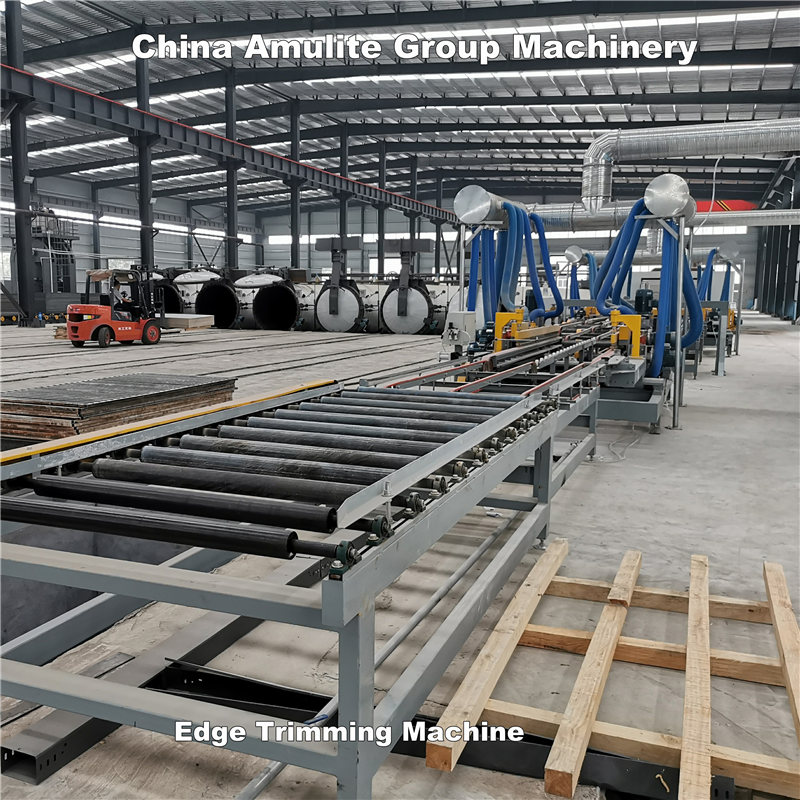

14. Edging Trimming System

The Edge Trimming Machine Inonyanya Kuumbwa NeMasheets Feeding Roller Table,Longitudinal Edge Trimming Machine, Steering Table, Transverse Edge Trimming Machine,Sheets Discharging Roller Table, Electric Cabinet, Air Cabinet, Etc;

Edging Trimming Machine Inoshandiswa Kugadzira Edging uye Kucheka yeFiber Cement Board, Wobva warongedza Kuti Zvipedzwe Zvigadzirwa.