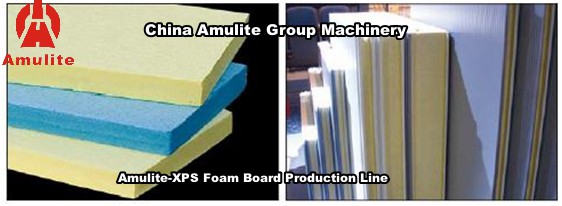

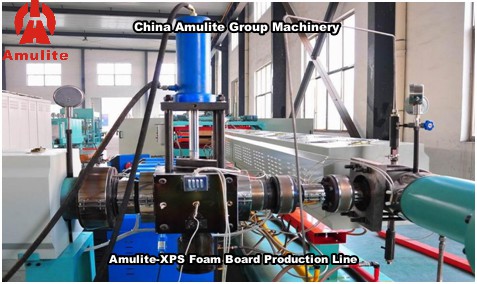

Amulite CO2 XPS Foam Board Production Line

Tsanangudzo Pfupi:

I.Technical Nhanganyaya

Chekutanga, kubatanidza symmetrical1y XPS zvinhu nezvimwe zvemubatsiri senge nucleant agent uye color batch; Kechipiri zviise muhopper yeGiredhi Iextruder nevacuum feeder automatical1y; Yetatu kunyunguduka uye plasticizing resin yakasarudzika yakagadzirwa simetrically, panguva imwe chete kubaya jekiseni rinoputira furo nekudzvanya kukuru. iyo ine resin yakanyunguduka;Kechina, kuzviisa muGiredhi IIextrusion system kuti isangane, sanganisa, wedzera kudzvanywa uye kutonhorera zvakare uye extruding foam board by yakakosha mold yebhodhi, wozotonhora nekugadzira bhodhi nekutonhodza uye formingdexiss..kifthly.kuisa bhodhi muGiredhi I draw-off system uye kutakura iwo Grade Il draw-off system nemarol1 ekufambisa;Chechitanhatu, kucheka tsvina kumucheto bysaw yezvose-kurutivi uye kupedzisa kucheka kwakachinjika maererano neseti 1;iyo yekutanga nhanho, kurongedza uye kuchengetedza.

Product Detail

Product Tags

Electricity Unit:

Main mota Beide Brand (Siemens Standard Motors Ltd.)

Transducer Danfoss kana Siemens Brand

AC Contactor Siemens kana Schneider Brand Temperature controller mita Omron Brand kana Fuji Brand Voltage 380V,50HZ

AM-XPS75P/200 CO2XPS Foam Board Production Line

I.Technical Nhanganyaya

Kutanga, kusanganisa symmetrically XPS zvinhu nezvimwe zvinhu zvemubatsiri senge nucleant agent uye color batch;Chechipiri zviise muhopper yeGrade I extruder nevacuum feeder otomatiki;Chechitatu kunyunguduka uye plasticizing resin neyakagadzirirwa screw symmetrically, panguva imwe chete jekiseni furo agent nekumanikidza kwakanyanya uye nekuisanganisa neresin yakanyunguduka;Chechina, kuaisa muGiredhi II extrusion system kunyunguduka, kusanganisa, kuwedzera kumanikidza uye kutonhorera zvakare uye kuburitsa furo bhodhi nechakakosha mold yebhodhi, wozotonhora nekuumba bhodhi nekutonhodza nekugadzira mudziyo; Chechishanu, kuisa bhodhi muGiredhi I kudhirowa- off system uye kuvatakura

kupinda muGiredhi II yekudhirowa-off system nekutakura mitsetse;Chechitanhatu, kucheka marara

saha yemativi ese maviri uye kupedzisa kucheka kwakachinjika maererano nehurefu hwakatarwa;danho rekupedzisira, stacking uye kuchengetedza.

II.The Main Material

1> XPS resin

2> Foam agent & batsira foam agent 3> Nucleant agent

4> Batch yemavara

5> Zvimwe zvinhu zvinobatsira

Ongorora: Isu tinopa vatengi vedu zvinyorwa zvekushandisa, rudzi rwezvinhu uye hukama magwaro ehunyanzvi mushure mekusaina chibvumirano.

Machine Component

1> Purasitiki musanganisi 1 seti

2> Giredhi I extrusion system 1 set

3> CO2foam agent jekiseni system 1 set 4> Mubatsiri foam agent jekiseni system 1 set 5> CO2flow show system 1 set 6> HCFC Foam agent jekiseni system 1 set 7> Otomatiki net-exchange system 1 set

8> Giredhi II extrusion system 1 set

9> Extrusion kufa musoro 1 set

10> Calibrating uye draw-off system 1 set

11> Kuendesa uye kutonhora sisitimu 1 set

12> Giredhi II draw-off system 1 set

13> Lengthways yekucheka system 1 set

14> Horizontal yekucheka system 1 set

AM-75P/200 CO2XPS Foamed Board Production Line

1.Kudyisa system

2.AM75/44Twin-screw extruder 1 set

3.CO2foam agent jekiseni system1 set

4.Mubatsiri foam agent jekiseni system 1 set

5.Freon Foam mumiririri jekiseni system 1 set

6.CO2kuyerera show system 1 set

7.Automatic net-exchange system 1 set

8.Giredhi II extrusion system 1 set

9.Extrusion kufa musoro 1 set

10.Calibrating uye kudhirowa-off system 1 set

11.Kutumira uye kutonhora system 1 set

12.Giredhi II draw-off system 1 set

13.Kureba kucheka system 1 set

14.Horizontal kucheka system 1 set

15> Transverse kucheka system 1 set

15.Magetsi unit

XPS Foamed Board Recycling uye Pelletizer Machine

Model AM-XPS-JR100B

1> XPS foam board crusher mudziyo 1set

2> Single screw plasticizing uye extrusion mudziyo 1set

3> Sefa net-kuchinja mudziyo 1 set

4> Cooling tank 1 set

5> Kucheka pellet muchina 1 set

Ongorora: Iyo iri pamusoro chikamu chefoam mumiriri ndeye yako referensi, iyo chaiyo data inogadziridzwa zvichienderana nekudiwa kwezvinhu zvakabikwa uye musika.